get to know us

get to know us

For Processing

get to know us

get to know us

For Processing

For Processing

For Processing

Compost Machine

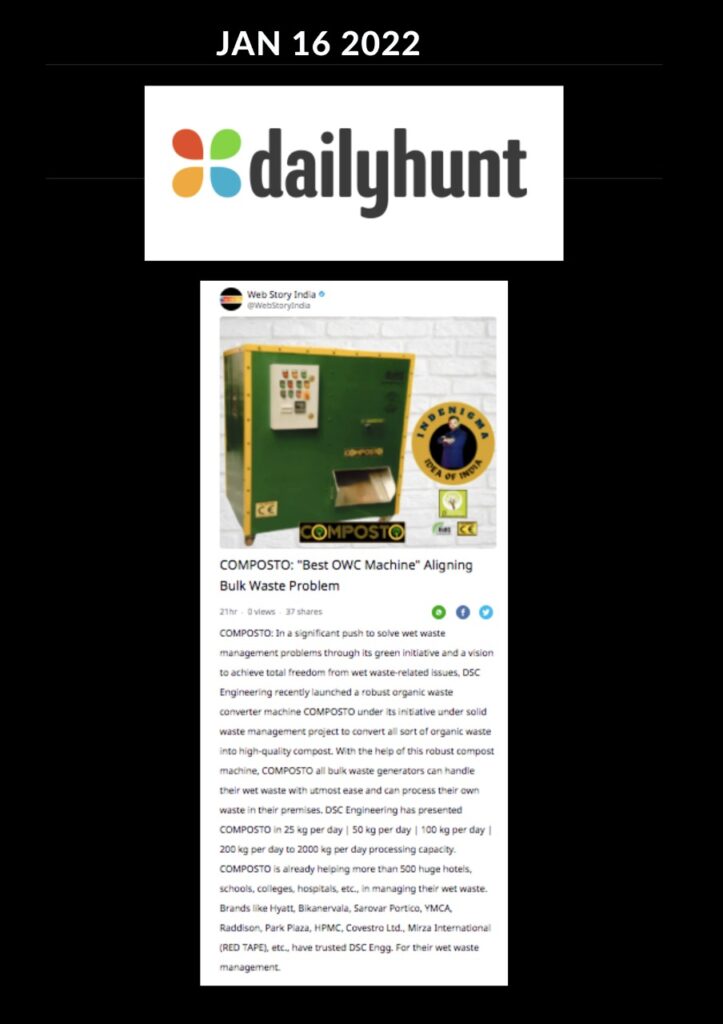

COMPOSTO stands at the forefront of the organic waste composter converter market. Whether it's your small restaurant/eatery or large hotel serving hundreds of customers every day, investing in COMPOSTO ensures the production of high-quality manure. Top-quality OWC by renowned compost machine manufacturers to revolutionize your waste management process. Our reliable and eco friendly solutions are designed to efficiently convert organic waste into valuable resources. This Organic waste composting machine is the best for your business purpose.

* Track record of 1005 successful installations

* Processing over 1 lac tonnes of waste Daily

* Network of 16 service centers

Find the best compost machine manufacturers suppliers in India. Contact us for more info. Call now @ 9958858881Check COMPOSTO COMMERCIAL ADVT.

Why do people consider COMPOSTO as best organic waste composting machine?

The success of Composto is attributed to 3 things:

1. Compact and user-friendly: organic waste compost machine are designed for convenience, allowing for easy relocation from one location to another. It’s super easy to work with and totally hassle-free.

2. Economical solution: Offering exceptional value for money, Composto caters to a wide range of settings, from small apartment complexes to large-scale establishments such as restaurants and hotels.

3. Dedicated support and service: Composto's commitment to customer satisfaction extends to top-notch support and servicing, ensuring that customers have a seamless experience throughout their usage of the product.

One standout feature of this organic compost machine is its inbuilt shredder, which ensures efficient waste processing. This means it can handle a wide range of organic materials, making it a versatile solution for waste management.

Top qualities of COMPOSTO : The Best Organic Waste Composting Machine

organic compost machine boasts a range of cutting-edge features designed to streamline the organic waste conversion process. The inclusion of a high-quality SS Mixing Brim ensures thorough mixing of organic material, promoting efficient decomposition.Ceramic-based star-rated heating system

Crafted with ceramic-based components, Composto OWCs not only ensure optimum performance but also stand as a testament to their energy efficiency. This star-rated heating system is designed to deliver consistent results while keeping power consumption in check.Durable construction for longevity

With a powder-coated surface finish, Composto machines can withstand the rigors of continuous operation. For those seeking an even higher level of durability, an option with a stainless steel body is also available.

Quality materials for contact parts

Organic waste composter machine features SS (304) components, ensuring that the critical parts are both corrosion-resistant and built to endure the demands of the waste conversion process.

Efficiency meets automation

Organic waste converter manufacturers, We operates on a fully automated system. This means you can expect seamless and hassle-free waste conversion without the need for constant manual intervention.Other features of organic waste composting machine

organic waste composter machine can process anywhere from 25 Kg to 5000 Kg of waste per day. Compliant with all Government of India SWM Rules, Composto offers a variety of models to accommodate different waste levels.

With a one-year warranty extendable up to five years, starting at just Rs. 95000, Composto provides an affordable and comprehensive solution for small-scale users in compost machine segment at best price.

To buy a Composto waste converting machine for your restaurant, apartment or organization, simply reach out to our team for best compost machine price.

Give us a call at 9958858881 and we'll take care of everything from installation, commissioning, operator training to after-sales services.Best Compost Machine Manufacturers

Professional Team with long Industrial experience

Over 500 Successful Installations

Best in class Organic Waste Converter

Best after sales services

25 kg to 2000 kg per day capacity machines available

Most Convenient

Very Quickly processes food waste for composting

Lowest Price Guaranteed

Machine Available at Lowest price in market

Compliance

Food waste management as per govt. rules the best & safest way

Cleanliness

No bad smell, No Mess No pest problem

Looking for Best Compost Machine Manufacturers?

Organic Waste Converter Processing Video

Inbuilt shredder video

How COMPOSTO Helps In Composting Process

* Helps in volume reduction of huge oil ups of waste

* Helps in making best quality compost in just 9 days

* Helps bad Odour Control

* Makes composting ready to process very easily in its biological stage

* Prepares high quality manure in which all necessary nutrients present for plant growth

Other details about “COMPOSTO”

* Very compact unit available across organic waste converter machine segment

How COMPOSTO is most Robust OWC?

- COMPOSTO presents with inbuilt shredder solution.

- This fantastic composting machine is PLC Controlled.

- COMPOSTO offers best heating system.

- Hazardous gases control system.

Machine Certifications

Our Installations

Delhi (Hauz Khas)

Delhi (Chattarpur)

U.P (Noida)

Delhi (Malviya Nagar)

Punjab (Ludhiana)

U.P (Greater Noida west)

Delhi (Chandni Chowk)

Delhi (Nehru Place)

Delhi (Kapas Hera)

Uttrakhand(Dheradun)

Himachal Pradesh(Parwanoo)

Meerut

Brands Trusted Us

1 Lac Tonne

Waste processed

1 Million

Happy People

ANS: A compost machine, also known as a composting machine or composter, is a mechanical device designed to accelerate the decomposition of organic waste materials into nutrient-rich compost. It offers an efficient and convenient way to manage organic waste and create a valuable soil conditioner that can be used in gardening, agriculture, and landscaping. Here’s how a compost machine works:

Input of Organic Waste: Organic waste materials, such as food scraps, kitchen waste, garden trimmings, and even some paper products, are fed into the compost machine. It’s important to maintain a balanced mixture of “green” (nitrogen-rich) and “brown” (carbon-rich) materials for effective composting.

Aeration: Compost machines are equipped with mechanisms to ensure proper aeration. This is vital because the microorganisms responsible for decomposition require oxygen to thrive. Some composters use tumbling or turning mechanisms, while others have built-in ventilation systems to facilitate airflow.

Moisture Control: Maintaining the right level of moisture is essential for composting. Compost machines often have features to regulate moisture, ensuring the compost pile remains damp but not waterlogged. Proper moisture levels promote microbial activity.

Temperature Control: Compost machines can help maintain the optimal temperature for decomposition. Microbial activity generates heat, and the composter’s design can help retain this heat to accelerate the composting process. Some advanced models even have temperature monitoring and control systems.

Microbial Action: In the presence of oxygen, moisture, and the right balance of organic materials, beneficial microorganisms (bacteria, fungi, and other decomposers) thrive. These microorganisms break down the organic matter into simpler compounds, converting it into nutrient-rich humus over time.

Composting Phases: The composting process typically goes through several phases, including the initial decomposition, the mesophilic phase (moderate temperature), and the thermophilic phase (high temperature). Each phase contributes to the breakdown of organic matter and the elimination of pathogens and weed seeds.

Curing and Maturing: After the active composting phase, the compost needs to cure and mature. This stage allows the compost to stabilize and become a finished product ready for use in gardening or agriculture. The compost machine may have a separate curing chamber or area for this purpose.

Output of Finished Compost: Once the composting process is complete, the machine provides access to the finished compost. It can be removed from the composter and used to enrich soil, improve its structure, retain moisture, and provide essential nutrients for plant growth.

Compost machines are available in various sizes and types, ranging from small, household composters to large, commercial-scale units. Their efficiency in producing high-quality compost makes them a sustainable solution for managing organic waste and promoting environmental conservation.

Ans: Using a compost machine for organic waste offers several significant environmental benefits, making it an eco-friendly and sustainable waste management solution. Here are the key environmental advantages:

Reduction of Landfill Waste: One of the most notable benefits is the diversion of organic waste from landfills. Organic materials decompose anaerobically in landfills, producing methane, a potent greenhouse gas that contributes to climate change. By composting organic waste instead, this harmful methane production is significantly reduced, mitigating the environmental impact of landfills.

Reduced Greenhouse Gas Emissions: Composting organic waste aerobically (with oxygen) produces carbon dioxide (CO2) and water vapor as byproducts, which are far less harmful to the environment than methane. This means that composting helps reduce overall greenhouse gas emissions and the carbon footprint of waste disposal.

Soil Improvement: The compost produced by these machines is a valuable soil conditioner. When added to gardens, farms, and landscapes, it improves soil structure, enhances moisture retention, and increases nutrient content. This reduces the need for chemical fertilizers, which can have negative environmental impacts when overused.

Conservation of Landfill Space: As composting diverts organic waste from landfills, it conserves precious landfill space. This is particularly crucial in areas with limited landfill capacity, where land use can be redirected for more sustainable purposes.

Natural Resource Conservation: By recycling organic waste through composting, there’s a reduced need for the extraction and production of synthetic fertilizers. This conserves natural resources, reduces energy consumption, and minimizes the environmental impact of chemical manufacturing.

Reduction of Soil and Water Pollution: Composting helps prevent the leaching of harmful chemicals, such as pesticides and herbicides, into the soil and water systems. This contributes to cleaner and healthier ecosystems, reducing the risk of contamination.

Support for Sustainable Agriculture: The use of compost in agriculture enriches soil with organic matter, fostering sustainable farming practices. Healthy soil is more resilient and requires less water and irrigation, which aids in water conservation efforts.

Habitat Preservation: As landfill expansion and management are resource-intensive, using compost machines to divert organic waste reduces the need to develop and destroy natural habitats for landfill expansion.

Air Quality Improvement: Proper composting techniques minimize foul odors and reduce the attraction of pests, which can be a common issue with landfill sites. This leads to improved air quality in the surrounding areas and reduces the need for pest control measures.

Local Ecosystem Benefits: Compost can also be used to restore or enhance local ecosystems, such as wetlands, parks, and green spaces. It enriches the soil and promotes biodiversity.

In summary, using a compost machine for organic waste management contributes significantly to environmental conservation and sustainability by reducing landfill waste, minimizing greenhouse gas emissions, improving soil quality, and supporting more eco-friendly agricultural practices. This not only benefits the environment but also promotes a healthier and more balanced ecosystem for present and future generations.

Ans: A compost machine can significantly help in reducing the burden on landfills through the efficient processing of organic waste. Here’s how:

Diversion of Organic Waste: Compost machine are designed to process organic waste, which typically constitutes a significant portion of the waste stream. By diverting this organic waste away from landfills, compost machines reduce the volume of waste that needs to be sent to landfill sites.

Reduced Methane Emissions: When organic waste decomposes in landfills, it often generates methane, a potent greenhouse gas. Composting organic waste in a controlled environment, as facilitated by compost machines, encourages aerobic decomposition. This aerobic process reduces methane emissions, thereby mitigating the environmental impact associated with landfills.

Extended Landfill Lifespan: With less organic waste entering landfills, these sites experience reduced pressure and slower filling rates. This, in turn, extends the lifespan of landfills, delaying the need for costly expansions or the creation of new landfill sites.

Conservation of Land: Land is a finite resource, and landfill sites take up valuable land that can be repurposed for more sustainable uses. By reducing the need for new landfill sites, compost machines contribute to land conservation efforts.

Creation of Valuable Compost: Compost machines convert organic waste into nutrient-rich compost. This compost can be used in agriculture, horticulture, and landscaping. By recycling organic waste into a valuable resource, compost machines complete the cycle and reduce the need for chemical fertilizers, further benefiting the environment.

Promotion of Sustainable Practices: Compost machines not only reduce the burden on landfills but also promote sustainable waste management practices. They encourage individuals, businesses, and communities to take responsibility for their organic waste and actively participate in environmentally friendly solutions.

In summary, compost machines are instrumental in reducing the burden on landfills by diverting organic waste, mitigating greenhouse gas emissions, and extending the lifespan of landfill sites. They play a vital role in shaping a more sustainable and environmentally responsible future.

Ans: Compost machines are versatile and can process a wide range of organic waste materials. The types of organic waste that can be effectively processed using a compost machine include:

Kitchen Scraps: This category includes fruit and vegetable peels, coffee grounds, eggshells, and food leftovers.

Yard Waste: Compost machines can handle grass clippings, leaves, twigs, and small branches.

Garden Waste: Dead plants, weeds, and garden trimmings are suitable for composting.

Agricultural Residues: Crop residues and plant matter from farms can be composted to create valuable organic matter.

Paper Products: Some compost machines can process shredded paper, cardboard, and paper napkins.

Wood Chips: Small wood chips or sawdust from woodworking projects can be added to the compost pile.

Manure: Animal manure, such as from cows, horses, and poultry, can be composted when properly managed.

Straw and Hay: These agricultural byproducts can be composted when they are no longer needed for livestock bedding.

Coffee Filters: Used coffee filters, especially those made of unbleached paper, can be included in compost.

Tea Bags: Many tea bags are biodegradable and can be composted.

Houseplant Trimmings: Trimmings and dead leaves from indoor plants are suitable for composting.

Small Amounts of Sawdust: If generated from non-treated wood, small quantities of sawdust can be composted.

Fruit and Vegetable Waste: In addition to kitchen scraps, fruit and vegetable waste from processing and juicing can be composted.

Natural Fibers: Organic materials like cotton and wool, as long as they are free from synthetic materials, can be added to the compost pile.

It’s important to note that while compost machines can process a variety of organic waste, certain items should be avoided in the composting process, such as diseased plants, meat and dairy products, and non-organic materials like plastics. Proper composting techniques and monitoring are essential to ensure a healthy and effective composting process.

Ans: When choosing a compost machine, several key components and features should be considered to ensure that it meets your specific needs and requirements. Here are some of the most important factors to take into account:

Capacity: Determine the amount of organic waste you generate regularly to select a compost machine with the appropriate capacity. Machines come in various sizes, from small units for households to large industrial-scale models for institutions and municipalities.

Type of Composting: There are two primary types of composting: batch composting and continuous composting. Batch composters fill up and process compost in batches, while continuous composters can process waste continuously. Choose the type that suits your needs and space.

Aeration System: Adequate aeration is crucial for efficient composting. Look for machines with built-in aeration systems that ensure the compost pile receives the oxygen it needs.

Moisture Control: A good compost machine should have moisture control features to maintain the ideal level of moisture in the compost pile. This is essential for effective decomposition.

Temperature Control: Temperature plays a significant role in the composting process. Machines with temperature control systems can optimize the composting conditions for faster and more efficient results.

Shredder or Grinder: Some compost machines include a shredder or grinder to break down waste materials into smaller pieces, which can accelerate the composting process.

Turner Mechanism: In large-scale composting, a turner mechanism may be necessary to periodically mix and aerate the compost pile. This feature ensures even decomposition and prevents compaction.

Energy Source: Consider the energy source for the compost machine. Some models operate on electricity, while others may be gas-powered or manual. Choose the one that aligns with your energy resources and sustainability goals.

Durability: Ensure that the machine is built with high-quality, durable materials, especially for components that come into direct contact with the composting process. This ensures the longevity of the machine.

Ease of Operation: User-friendliness is essential. The machine should be easy to operate and maintain, with clear instructions and minimal complexity.

Training and Support: Check if the manufacturer or supplier offers training and support to help you operate the compost machine effectively. Proper training ensures successful composting.

Safety Features: Safety is paramount when working with machinery. Look for safety features such as emergency shut-offs and protective covers to prevent accidents.

Regulatory Compliance: Ensure that the compost machine meets any relevant regulatory requirements or standards in your area.

Price and Budget: Consider your budget and compare the features and capabilities of different compost machines to find one that offers the best value for your investment.

By carefully considering these components and features, you can select a compost machine that aligns with your specific composting goals, whether you’re a household, a business, or an institution.

Ans: Compost produced by a compost machine offers a wealth of benefits for gardening and agriculture. Here are some of the key advantages:

Nutrient-Rich Soil Amendment: Compost is a valuable soil amendment rich in essential nutrients, including nitrogen, phosphorus, and potassium. These nutrients are vital for plant growth and development. When added to soil, compost enhances its fertility, providing plants with the nutrients they need to thrive.

Improved Soil Structure: Compost helps improve soil structure by increasing its water retention capacity and preventing it from becoming too compacted. It also enhances aeration, allowing plant roots to access oxygen and nutrients more effectively. This results in healthier, more robust root systems.

Enhanced Water Retention: Compost acts as a natural sponge, increasing the soil’s water-holding capacity. This means that soil enriched with compost can retain moisture for longer periods, reducing the frequency of irrigation and helping plants withstand drought conditions.

pH Regulation: Compost can help regulate soil pH. It acts as a buffer, making the soil less susceptible to extreme pH swings. This is especially beneficial for regions with acidic or alkaline soils.

Microbial Activity: Compost is teeming with beneficial microorganisms such as bacteria, fungi, and earthworms. These microorganisms support the breakdown of organic matter in the soil and contribute to nutrient cycling. They also help suppress harmful pathogens and pests, promoting overall soil health.

Reduced Need for Chemical Fertilizers: By providing a natural source of nutrients, compost reduces the reliance on chemical fertilizers. This not only reduces the cost of fertilization but also minimizes the risk of nutrient runoff, which can harm the environment.

Weed Suppression: Compost can help suppress weed growth. It creates a physical barrier that hinders weed establishment and growth, reducing the need for herbicides and manual weeding.

Sustainable Agriculture: Incorporating compost into agricultural practices supports sustainable farming. It reduces the environmental impact of agriculture by improving soil quality, minimizing soil erosion, and promoting efficient nutrient management.

Increased Crop Yields: Healthy, well-amended soil results in increased crop yields. Compost’s ability to enhance soil fertility and structure directly translates to improved plant growth and productivity.

Environmental Benefits: The use of compost reduces the volume of organic waste sent to landfills, lowering the environmental impact associated with waste disposal. This promotes a more sustainable and eco-friendly approach to waste management.

Soil Restoration: Compost can help restore degraded or contaminated soils by detoxifying contaminants and revitalizing the soil’s ability to support plant life.

In summary, compost produced by a compost machine is a powerful tool for improving soil quality and promoting sustainable gardening and agriculture. Its ability to enrich the soil with essential nutrients, enhance water retention, and support beneficial microbial activity makes it an invaluable resource for farmers, gardeners, and anyone seeking to cultivate healthy and productive plants.

Ans: Yes, there are different sizes and scales of compost machines designed to cater to various applications and needs. The choice of compost machine size depends on the volume of organic waste generated and the specific requirements of the user. Here are some common scales of compost machines:

Household or Small-Scale Compost Machines: These are designed for individual households and small-scale composting. They have a relatively lower capacity, making them suitable for kitchen scraps, yard waste, and smaller quantities of organic material. They are compact and user-friendly, making them ideal for residential use.

Community or Commercial Compost Machines: These machines are larger and can handle a higher volume of organic waste. They are suitable for applications like community gardens, schools, restaurants, and small businesses. They have increased capacity and may include additional features such as shredders and automatic aeration systems.

Industrial or Large-Scale Compost Machines: These machines are designed for handling substantial volumes of organic waste, making them suitable for municipalities, waste management facilities, large institutions, and industrial settings. They are equipped with advanced features, including powerful shredders, automated moisture and temperature control systems, and turner mechanisms for efficient composting on a larger scale.

Continuous Composters: Some compost machines operate continuously, allowing for the constant processing of organic waste. These machines are suitable for applications where waste generation is ongoing, such as industrial or institutional settings.

Batch Composters: Batch composters, as the name suggests, process organic waste in batches. They are loaded with waste, and once one batch is complete, it is removed, and a new batch is started. These are commonly used in smaller-scale applications.

On-Site Composting Systems: These compost machines are designed for on-site waste management, reducing the need for waste transportation. They are often found in restaurants, hotels, and institutions, where waste is generated daily.

Vermicomposters: Vermicomposting machines use earthworms to break down organic waste. They are suitable for small-scale applications, particularly in households and educational settings, where vermicomposting is favored.

Mobile Composters: Some compost machines are mobile, allowing them to be transported to various locations for specific composting projects. These are often used for community events, festivals, or temporary waste management needs.

The choice of the compost machine scale depends on factors such as the quantity of organic waste generated, available space, budget, and the specific goals of the composting project. Selecting the right size and scale ensures efficient and effective organic waste management.

Ans: Aeration and moisture control play critical roles in the composting process when using a machine. These factors are essential for creating the optimal conditions required for efficient and effective composting. Here’s an explanation of their roles:

Aeration:

- Oxygen Supply: Aeration involves ensuring that the compost pile receives an adequate supply of oxygen. Oxygen is essential for the growth and activity of aerobic microorganisms, which are responsible for breaking down organic matter. These microorganisms require oxygen to carry out the decomposition process effectively.

- Preventing Anaerobic Conditions: Without proper aeration, compost piles can become compacted and oxygen-deprived, leading to anaerobic conditions. In anaerobic conditions, different microorganisms dominate, and the composting process becomes slower and less efficient. It can also produce foul odors.

- Reducing Methane Emissions: Proper aeration helps reduce methane emissions. Methane is a potent greenhouse gas produced in anaerobic conditions during the decomposition of organic waste. Adequate aeration shifts the process toward aerobic decomposition, which minimizes methane generation.

Moisture Control:

- Maintaining the Right Moisture Level: Moisture control involves maintaining the correct level of moisture in the compost pile. The ideal moisture content for composting is typically around 50-60%. This level ensures that the compost pile is neither too dry nor too wet.

- Facilitating Decomposition: Adequate moisture is necessary for microorganisms to function effectively. It facilitates the chemical reactions involved in decomposition. If the compost pile becomes too dry, microbial activity slows down, and decomposition becomes inefficient. Conversely, if it becomes too wet, the pile may become anaerobic and produce unpleasant odors.

- Preventing Leachate: Excessive moisture can result in leachate, a liquid that drains from the compost pile. Leachate can contain nutrients and may have a negative environmental impact. Proper moisture control helps prevent the leachate from becoming a problem.

Compost machines typically include features to manage aeration and moisture. They may have fans, blowers, or turning mechanisms that promote aeration by ensuring a steady flow of oxygen. Some machines also incorporate automated moisture control systems that monitor and adjust the moisture level as needed to maintain the ideal conditions for composting.

Proper aeration and moisture control are crucial for accelerating the composting process, preventing odors, reducing greenhouse gas emissions, and producing high-quality compost. When these factors are managed effectively using a compost machine, the composting process becomes more efficient and environmentally friendly.

Ans: Yes, compost machines can be used in both residential and industrial settings, as well as various applications in between. Their versatility and scalability make them suitable for a wide range of settings. Here’s how compost machines are used in different settings:

Residential Settings:

- Households: Compost machines designed for households are compact and user-friendly. They are capable of processing smaller quantities of organic waste typically generated by families. These machines make home composting convenient and help reduce the need for waste collection and disposal.

Community and Commercial Settings:

- Community Gardens: Community compost machines are suitable for shared garden spaces, helping gardeners manage organic waste efficiently. These machines can handle a moderate volume of waste, making them ideal for group composting efforts.

- Schools and Educational Institutions: Compost machines are used in schools and colleges to teach students about sustainability and responsible waste management. They offer hands-on learning experiences and produce valuable compost for school gardens.

- Restaurants and Cafes: Commercial compost machines help food establishments manage kitchen waste, including food scraps and coffee grounds. They reduce the environmental impact of food service businesses by diverting organic waste from landfills.

- Hotels and Resorts: Hospitality units use compost machines to process organic waste generated by guests and kitchen operations. The resulting compost can be used in landscaping and gardens on the premises.

Municipal and Industrial Settings:

- Municipalities: Many municipalities and waste management facilities invest in industrial-scale compost machines. These machines can process substantial volumes of organic waste from various sources, reducing landfill reliance and lowering greenhouse gas emissions. They are a key component of municipal composting programs.

- Industrial Facilities: Some large industrial facilities, such as food processing plants, use compost machines to manage their organic waste efficiently. These machines are designed to handle the specific waste streams generated by industrial operations.

- Agricultural and Farming Operations: Compost machines are used on farms to convert agricultural residues and organic matter into valuable compost. This helps improve soil fertility and enhances crop yields.

Institutional Settings:

- Prisons, Military Bases, and Hospitals: Compost machines are utilized in institutional settings to manage organic waste generated on-site. They offer a sustainable waste management solution and contribute to the facilities’ environmental goals.

Special Events and Festivals:

- Temporary Use: Mobile compost machines can be transported to special events and festivals to manage organic waste during the event. They reduce the environmental impact of large gatherings and demonstrate responsible waste management practices.

The versatility of compost machines and the variety of sizes and features available allow them to be tailored to specific applications and settings. Whether it’s a small-scale household compost machine or a large industrial composting system, these machines contribute to more sustainable and eco-friendly waste management in a wide range of environments.

Ans: Operating a compost machine effectively requires some training and knowledge to ensure that the composting process is efficient, environmentally responsible, and free from common issues. Here are the key areas of training and knowledge required:

Machine Operation: Users should understand how to operate the compost machine safely and efficiently. This includes starting and stopping the machine, adjusting settings (if applicable), and monitoring its performance.

Waste Segregation: Proper waste segregation is essential. Users need to know what types of organic waste are suitable for composting and what should be excluded (e.g., meat, dairy, diseased plants). Effective waste segregation prevents contamination and odor issues.

Loading and Layering: Users should be trained in how to load the machine with organic waste. This often involves layering different types of waste to promote balanced decomposition and prevent compaction.

Aeration and Turning: Understanding how the compost machine’s aeration and turning mechanisms work is crucial. Users should know when and how to aerate or turn the compost pile to maintain optimal conditions for decomposition.

Moisture Management: Users should be aware of the importance of moisture control. They need to monitor the moisture level and know how to adjust it if it becomes too dry or too wet.

Temperature Monitoring: Regular temperature monitoring is necessary to gauge the progress of composting. Users should be familiar with the target temperature range and how to interpret temperature fluctuations.

Compost Maturity: Users should know how to recognize when the compost is mature and ready for use. Mature compost is characterized by its dark color, earthy smell, and crumbly texture.

Health and Safety: Safety precautions are essential, especially for larger compost machines. Users should understand safety guidelines, including emergency shut-off procedures and the importance of protective gear.

Environmental Regulations: Depending on the location and scale of composting, users may need to be aware of local environmental regulations and permits related to composting activities.

Troubleshooting: Users should be able to identify common issues such as odors, imbalances in the compost pile, or pests, and know how to address them effectively.

Record-Keeping: Keeping records of composting activities can be valuable for monitoring progress and identifying any patterns or issues that may arise over time.

Community and Public Education: In community settings, those responsible for operating compost machines may need to educate others, such as students or community members, on composting principles and practices.

Training can be provided by compost machine manufacturers, waste management professionals, or environmental organizations. It is essential to ensure that those operating compost machines have the knowledge and skills required to achieve successful composting outcomes and maintain a clean and efficient composting process.

Ans: Compost machines play a significant role in reducing greenhouse gas emissions through their impact on the decomposition of organic waste. Here’s how they contribute to this environmental benefit:

Shift from Landfills to Composting: Compost machines divert organic waste away from landfills. When organic waste, such as food scraps and yard trimmings, ends up in landfills, it decomposes in anaerobic conditions (without oxygen), leading to the production of methane, a potent greenhouse gas. Composting, facilitated by compost machines, shifts the decomposition process from methane-producing anaerobic conditions to aerobic conditions, significantly reducing methane emissions.

Aerobic Decomposition: Compost machines create controlled, aerobic environments for the decomposition of organic waste. In these conditions, aerobic microorganisms break down organic matter more efficiently and produce carbon dioxide (CO2) as a byproduct, which is less potent as a greenhouse gas than methane. The carbon dioxide produced during aerobic decomposition is part of the natural carbon cycle and is less harmful to the environment.

Reduced Methane Emissions: By preventing the formation of methane in landfills and promoting the generation of CO2 through aerobic decomposition, compost machines help mitigate the impact of greenhouse gas emissions. Methane is over 25 times more effective at trapping heat in the atmosphere than carbon dioxide, making it a major contributor to global warming.

Enhanced Soil Carbon Sequestration: The compost produced by compost machines is a stable form of organic matter. When added to soil, compost enhances carbon sequestration in the ground, helping to offset greenhouse gas emissions. This is because the carbon in compost becomes a part of the soil’s organic carbon pool, where it can remain for an extended period.

Decreased Fossil Fuel Use: Compost machines reduce the need for waste transportation to landfills, which can require the use of fossil fuels. When organic waste is composted on-site or at a nearby facility, transportation-related greenhouse gas emissions are minimized.

Promotion of Sustainable Practices: Compost machines promote sustainable waste management practices and raise awareness about the environmental impact of organic waste. This leads to more responsible waste disposal behaviors, reducing the amount of organic waste that would otherwise end up in landfills.

Closed Nutrient Cycle: The compost produced by compost machines can be used to enrich soil in agriculture and horticulture. When plants grow in compost-amended soil, they absorb carbon dioxide from the atmosphere during photosynthesis, contributing to a closed nutrient cycle that sequesters carbon and reduces overall emissions.

In summary, compost machines significantly reduce greenhouse gas emissions by shifting the decomposition of organic waste from methane-producing landfills to aerobic composting conditions. This environmentally responsible approach not only helps combat global warming but also enriches soil, promotes sustainable practices, and reduces the environmental impact of waste management.

Ans: Compost machines, like any other equipment, require ongoing maintenance and servicing to ensure their smooth and efficient operation. The specific maintenance needs may vary depending on the type and size of the compost machine, but here are some common maintenance and servicing tasks typically associated with compost machines:

Regular Cleaning: Cleaning the compost machine is essential to prevent the accumulation of organic residues, which can lead to odors, pests, and blockages. Routine cleaning of components such as chutes, conveyor belts, and collection bins is necessary.

Oil and Lubrication: Some compost machines may have moving parts that require lubrication. Regularly checking and lubricating bearings, chains, and other moving components is important to prevent wear and tear.

Component Inspection: Routine inspections of the machine’s components, including fans, blowers, and turning mechanisms, are crucial to ensure they are functioning properly. Any damaged or malfunctioning parts should be repaired or replaced promptly.

Electrical System Check: For electrically powered compost machines, checking the electrical system, wiring, and connections is necessary to prevent electrical issues or malfunctions.

Temperature Monitoring System: Compost machines with temperature monitoring systems should be calibrated and checked to ensure they accurately reflect the compost pile’s temperature. Accurate temperature monitoring is essential for gauging the progress of composting.

Aeration System Maintenance: Aeration components, such as fans or blowers, should be maintained to ensure they provide adequate oxygen to the compost pile. Blockages or damaged components can impede proper aeration.

Moisture Control System: Machines with automated moisture control systems need to be monitored and calibrated to maintain the desired moisture levels in the compost pile.

Turner Mechanism: Compost machines with turning mechanisms may require inspections and maintenance to ensure that the compost pile is being turned at regular intervals. This helps distribute heat and oxygen evenly and prevent compaction.

Safety Checks: Safety features, such as emergency shut-off mechanisms and protective covers, should be regularly inspected and tested to ensure they function as intended.

Training and User Knowledge: Periodic training and refresher courses for those operating the compost machine are essential to ensure that it is used correctly and effectively.

Calibration and Programming: Machines with automated controls may require periodic calibration and programming adjustments to maintain optimal composting conditions.

Wear and Tear: Over time, various components of the compost machine may experience wear and tear. These components should be inspected and replaced as needed to prevent performance issues.

Record-Keeping: Keeping records of maintenance activities, such as cleaning schedules, repairs, and component replacements, can help in tracking the machine’s performance and ensuring that maintenance tasks are not overlooked.

The frequency of maintenance tasks may vary based on factors such as the type of compost machine, the volume of organic waste processed, and environmental conditions. Regular maintenance and servicing help extend the lifespan of the compost machine, prevent breakdowns, and ensure that it continues to operate efficiently and safely.

Ans: Compost machine manufacturers play a crucial role in assisting customers with the selection and installation of compost machines. Their expertise and support can simplify the process and ensure that the chosen machine meets the specific needs and requirements of the customer. Here’s how manufacturers can help:

Product Consultation: Manufacturers can provide product consultation to help customers understand the different compost machine models available, their features, and their suitability for specific applications. This consultation includes discussing factors such as machine capacity, size, type of composting (batch or continuous), and automation options.

Customization: Manufacturers may offer customization options to tailor the compost machine to the customer’s specific needs. This can include adjusting the machine’s size, features, and controls to align with the customer’s goals and waste volume.

Site Assessment: Manufacturers can conduct site assessments to determine the best location for the compost machine and assess any site-specific requirements, such as electrical connections, space considerations, and environmental conditions.

Technical Support: Manufacturers provide technical support to assist customers in understanding the operation and maintenance of the compost machine. This support may include training sessions, user manuals, and troubleshooting guidance.

Compliance and Regulations: Manufacturers are knowledgeable about environmental regulations and compliance standards related to composting. They can help customers navigate these regulations and ensure that their composting operations meet legal requirements.

Installation Services: Many manufacturers offer installation services, where their technicians will install the compost machine at the customer’s site. This ensures proper setup and minimizes the risk of installation errors.

Waste Analysis: Manufacturers can help customers conduct a waste analysis to determine the composition of their organic waste stream. This information assists in selecting the most suitable compost machine and optimizing the composting process.

Cost Estimation: Manufacturers can provide cost estimates for both the purchase of the compost machine and ongoing operational expenses. This helps customers plan their budgets effectively.

Supply of Spare Parts: Manufacturers typically stock spare parts for their machines. This ensures that customers can access replacement components quickly in case of breakdowns or routine maintenance needs.

Warranty and Service Contracts: Manufacturers often provide warranties for their machines and may offer service contracts for ongoing maintenance and support.

References and Case Studies: Manufacturers can provide references and case studies to showcase successful composting projects using their machines. This helps customers understand the real-world impact and benefits of their investment.

Environmental Benefits: Manufacturers can educate customers on the environmental benefits of composting and the reduction of greenhouse gas emissions. This information may be valuable for organizations with sustainability goals.

By offering these services and support, compost machine manufacturers help customers make informed decisions, choose the right machine for their needs, and ensure a smooth installation process. This collaboration ensures that customers get the most out of their compost machines for efficient organic waste management.

5 Things You Must Check Before Buying Compost Machine

- Compost machine should have inbuilt shredder (The Golden Rule- more the surface area to microbes the easier and fast the decomposition process will be).

- Power of motor attached to shredder should be apt and match shredder capacity

- Shredder is needed for only hard materials – if don’t have hard material food waste like bones etc. then there is no need to spend unnecessary on with shredder machines (Without shredder compost machine is available at much lower prices).

- Composting is not a mechanical process so ask for compost quality certificate if anyone offering 24 hours composter.

- Contact parts of compost machine which will come into touch with garbage should preferably built with stainless steel as it will not take rust and will increase machine life.